Alumina Bricks

Overview:

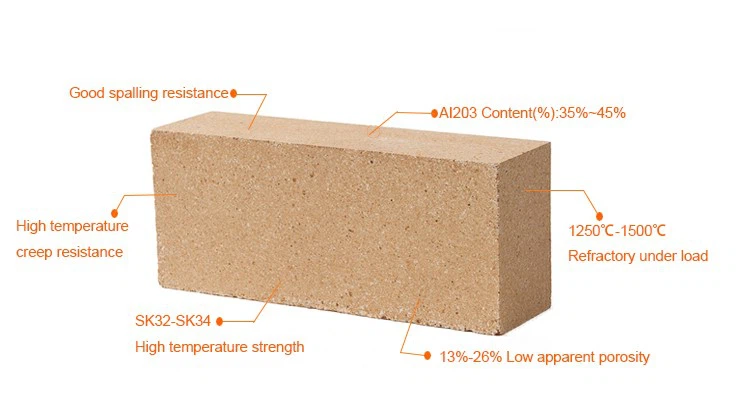

Alumina bricks are high-temperature refractory bricks made primarily from alumina (Al2O3). These bricks are designed to withstand extreme heat, mechanical wear, and chemical corrosion, making them ideal for industrial applications.

| PARTICULARS | APPLICATION AREA | Al2O3 % Min. | Fe2O3 % Max. | P.C.E.(O.C) Min. | POROSITY (%) Max. | CCS (kg/cm2) No | RUL (Ta °C) Max. | B.D. (gntx) Me. | PLC (%) Max. |

|---|---|---|---|---|---|---|---|---|---|

| Able 80 | EAF Rest, Ladle Lining & other High heat duty Special application. | 80 | 1.8 | 37 | 20 | 600 | 1520 | 2.75 | ±0.5 at 1500 °C/2hrs |

| Able 85 | Special type of high temperature & high abrasion application. | 85 | 1.5 | 35 | 19 | 700 | 1550 | 2.80 | ±0.5 at 1500 °C/2hrs |

| Able 80 P | Phosphate bonded bricks for reheating furnace bottom and other special applications where abrasion is high. | 80 | 1.8 | 37 | 17 | 750 | 1500 | 2.80 | ±0.8 at 1500 °C/2hrs |

| Able 85 P | Phosphate bonded bricks for Aluminium melting, Holding furnace & Reheating furnace bottom. | 85 | 1.5 | 38 | 17 | 900 | 1530 | 2.85 | ±0.8 at 1500 °C/2hrs |

| Able 88 RFB | An excellent material for coal-fired reheating furnace bottom. | 88 | 1.8 | 38 | 15 | 1000 | 1580 | 2.90 | ±0.5 at 1500 °C/2hrs |

| Able 50 S | Dense bricks for Petroleum, Fertilizer & Aluminum Industries. | 50 | 2.0 | 34 | 21 | 400 | 1450 | 2.30 | ±1.0 at 1500 °C/2hrs |

| Able 55 S | Dense volume stable bricks for Reheating furnace roof & Petroleum plants. | 55 | 2.0 | 35 | 22 | 450 | 1460 | 2.35 | ±1.0 at 1500 °C/2hrs |

| Able Sill | For Glass industries & Frit furnace applications. | 58 | 1.5 | 36 | 22 | 400 | 1520 | 2.35 | ±0.5 at 1500 °C/2hrs |

| Able 60 S | For Cs2 furnace, Sulphur furnace, Alkali resistant bricks for Cement rotary kiln. | 60 | 2.0 | 36 | 22 | 450 | 1500 | 2.40 | ±0.8 at 1500 °C/2hrs |

| Able 62 D | Low porosity dense bricks for Blast furnace, Glass tank furnace & Frit furnace. | 62 | 1.5 | 36 | 16 | 600 | 1520 | 2.55 | ±0.5 at 1500 °C/2hrs |

| Able 70 S | For Burning zone of Cement rotary kiln. | 70 | 3.0 | 36 | 23 | 500 | 1460 | 2.65 | ±2.0 at 1500 °C/2hrs |

| Able 70 L | For Burning zone of Cement rotary kiln. | 70 | 2.5 | 36 | 23 | 500 | 1480 | 2.60 | ±2.0 at 1500 °C/2hrs |

| Able 70 LI | Lime kiln & Burning zone of Cement rotary kiln. | 70 | 1.5 | 37 | 22 | 600 | 1520 | 2.55 | ±0.5 at 1500 °C/2hrs |

Properties:

Alumina bricks exhibit excellent thermal stability, high strength, and resistance to slag and acid attacks. They are available in various grades, depending on their alumina content, which determines their heat resistance and durability.

Applications:

These bricks are widely used in high-temperature environments such as steel furnaces, glass kilns, cement rotary kilns, and petrochemical industries. Their ability to resist thermal shock and mechanical stress makes them essential for demanding industrial processes.